Our country issued the "Plastic Restriction Order" on June 1, 2008, prohibiting the production and sale of plastic bags with a thickness of less than 0.025 mm. Reuse to reduce white pollution.

In January 2020, what the industry called "the most stringent plastic restriction order in history" was issued, which explicitly prohibited the production and sale of plastic products including "plastic shopping bags with a thickness of less than 0.025 mm", and prohibited plastic products including " Non-degradable plastic bags" plastic straws, etc.

At present, many countries in the world, including Europe, America, Africa, and Asia, have banned or restricted plastics. In the future, more and more countries will ban plastics. At present, the mainstream environmental protection bags on the market include paper bags, non-woven bags, degradable plastic bags and so on.

Although non-woven bags are more durable and can be reused, in fact, non-woven bags are not "cloth" bags, nor do they belong to the "cloth bags" mentioned in the new policy of restricting plastics. The main raw materials of non-woven fabrics are Polypropylene (pp), which is essentially a plastic product, degrades as slowly as traditional plastic bags in the natural environment. In addition, in order to reduce costs, some businesses use non-woven materials that are very light and thin, and are easily damaged and cannot be reused. In order to make the non-woven bag more textured and printed more beautifully, many businesses will cover the non-woven fabric with film, which aggravates the plastic pollution. The non-woven bag is environmentally friendly, which means that it can be used multiple times. If the non-woven bag is also disposable, it will cause more pollution than plastic bags, so I believe that the use of non-woven bags will eventually be constrained.

There are also degradable plastic bags. The "degradable plastic bags" currently used on the market are difficult to degrade completely, because the current cost of degradable materials is very high,A ton is about 30,000, but the degradable materials used in the market are about 20,000 a ton.,or even lower. Since degradable plastic bags cannot be identified with the naked eye, it is impossible for you to do all the tests. It is not ruled out that businesses will cut corners to reduce costs. It is conceivable that whether this can be degraded is a question. Although degradable plastic bags have these problems, their functionality is also difficult to replace. There will still be many places where they need to be used, but the amount of use will gradually decrease, and those that can be replaced will be gradually replaced.

Whether it is to increase the thickness or increase the fastness, how many people can reuse it now?

For these "disposable" non-woven bags or thickened plastic bags, it is a waste of resources, and it also violates the original intention of the "plastic restriction order", but aggravates plastic pollution. Although the current plastic restriction policy is not perfect and may not be strictly implemented, the restrictions on plastic products will only become more and more strict in the future. This is a general trend of global consensus, so paper bags will be the best choice.

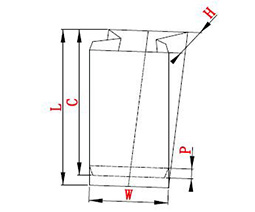

The use of paper bags in foreign countries has become very common. We have been specializing in the production of paper bag machines for 16 years. Before, our paper bag machines were mainly exported to foreign countries. As countries pay more and more attention to environmental protection, the demand for paper bags is also increasing. , After 16 years of design and research and development, the types of paper bag machines are becoming more and more complete, the sales volume is also increasing, the development cost in the early stage is gradually reduced, and the cost of the machine and paper bag is also getting lower and lower, the size of a shoe box The cost of the handbag is only about 0.3 yuan, and the application of paper bags is becoming more and more extensive, including catering takeaway, street snacks, shopping malls, supermarkets, electronic devices, etc., and now they are widely used in China.

The investment of paper bag machine equipment can be as little as 100,000 yuan, and more than 100,000 yuan. That is to say, you can develop from the investment of 100,000 family workshops to hundreds of tens of millions of investment scale. In our It is not uncommon for such cases among customers. In the future, the demand for paper bags will only increase and the development space will be huge.

If you also want to join this industry, you can contact me at any time to purchase our equipment, we will provide services including on-site installation, commissioning, training, warranty and technical support, and will also provide you with information on various high quality raw material suppliers , Lilin Machinery looks forward to cooperating with you for a win-win situation!