The paper bag machine is a machine that takes a printed sheet of paper or laminated paper and automatically sucks up the paper, glues it into shape, creases it, glues the bottom and outputs it according to the required size, completing the production of paper bags in one go. Paper bag machine in the bag making process may appear in one way or another, you need to promptly investigate the causes and deal with the solution. Here to give you the automatic paper bag machine common three major troubleshooting methods.

First, the upper and lower pieces on the ban.

The upper and lower pieces of the inhibition refers to the bag-making before and after the double-sided is not aligned and presented problems

1, the reasons for the occurrence of:

(1) composite film thickness is not uniform, there is a ruffled edge;

(2) double floating roller tension is too small;

(3) some roller rotation is not smooth.

2、Solution:

(1) Check and adjust the relevant guide rollers (such as offset rollers, adjusting deflection rollers, etc.).

(2) adjust the double floating roller tension.

Second, the cover has spots, bubbles

Cover with spots, bubbles refers to the sealing surface is not flat

1, the cause of occurrence:

(1) heat sealing knife or heat sealing silicone pad is not flat.

(2) When heat sealing is carried out on the structure of moisture-absorbing raw materials such as rich nylon film, bubbles occur when the moisture-absorbing film absorbs moisture.

(3) Lack of heat sealing pressure.

(4) The use of one-component adhesives, such as neoprene adhesives, in the heat sealing bag-making. The heat seal cover is easy to present a small pit of uneven height.

2、Solution:

(1) replace the adhesive.

(2) Check or adjust the heat sealing knife and heat sealing silicone pad.

(3) Store the raw materials and semi-finished products properly to prevent them from absorbing moisture.

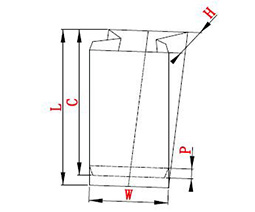

Three, scale error

1, the cause of occurrence:

Automatic paper bag machine operating factors, such as improper tension control, walking film rubber roller pressure cylinder pressure setting lack of pressure, etc.. Electric eye staring inhibition. The impact of plastic composite film bag-making processing speed. Automatic paper bag making machine bag length fixing system error is too large.

2, The solution:

To reduce the bag-making speed, and bag-making speed adjustment to be carried out slowly. Pre-adjusted film length (when adjusting the white bag) and the actual bag-making scale to be as accurate as possible. Check the degree of compression by the pressure film ruler, composite bag film friction coefficient is not appropriate. Adjust the rubber roller pressure, cylinder pressure and tension in all parts of the film. Check if there is a cursor printing problem or distance problem, and adjust it. Adjust the length setting system.