1. Adhesion problems. The adhesion is not good, and the ink film is easily peeled off after rubbing. Requires careful selection of resin, use of ink with better adhesion, do not adjust the ink to be used too thinly, or cover the surface of the printed product with protective varnish to meet more and more various packaging. The problem of adhesion of plastic film for printing.

2, through printing. Since the ink penetrates too deeply, the print can be seen on the back side of the paper. It is necessary to replace the thicker ink, reduce the printing pressure, and reduce the amount of ink.

3. Chemical pinholes. It mainly appears on the cellophane printing of moisture proof. There are many pinhole-like blank areas in the ink film. The distribution of pinholes is messy and the size is not uniform. Special additives to improve the wettability of the ink can be added, a small amount of plasticizer and appropriate solvent can be added, or the temperature in the printing shop can be increased, the humidity can be lowered, and new ink can be used instead.

4. Mechanical pinholes. This is caused by a number of reasons, a uniform size of sand holes that spread evenly throughout the print. Increasing press pressure, correcting the ink roller, increasing ink viscosity, and reducing ink dryness can all solve such problems.

LT Multi-colors Flexo printing machine

Introduction:

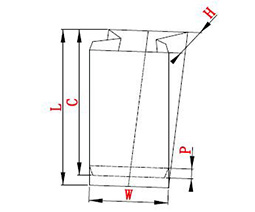

This machine is suitable for printing such packing materials as polyethylene, polypropylene plastic bag, glass paper and roll paper, etc. And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

Features:

1.using helical gear transmission, stable operation, low noise.

2.version and fall plate using pneumatic landing plate.

3.Deviation rectification control system of discharge automatic photoelectric sensor.

4.independent scraping knife scraping ink and automatic ink circulation system.

5.independent grouping type automatic ink mixing system, can be opened on demand, one or more groups of ink evenly

6.with ceramic anilox roller, high speed dot reproduction rate is high, screen printing layer is clear, three-dimensional feeling strong.

7.independent drying area, using central constant temperature control system and grouping control.