In today's eco-conscious world, the demand for sustainable packaging solutions is at an all-time high. Paper bags, known for their biodegradability and recyclability, have emerged as a popular alternative to plastic bags. Meeting this demand efficiently and effectively requires advanced machinery, and the high-speed paper bag machine stands out as the optimal choice for manufacturers looking to produce paper bags at scale.

1. Speed and Efficiency:

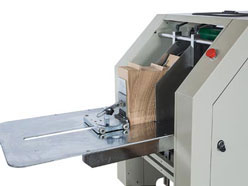

As the name suggests, high-speed paper bag machines are engineered for exceptional efficiency and productivity. These machines can produce a large volume of paper bags in a relatively short amount of time, maximizing output and reducing production costs. With advanced automation features, such as automatic paper feeding, cutting, and folding, these machines minimize manual intervention and streamline the manufacturing process.

2. Versatility in Bag Design:

High-speed paper bag machines offer versatility in bag design, allowing manufacturers to produce various types of paper bags to meet diverse market demands. Whether it's flat-bottom bags, square-bottom bags, or gusseted bags, these machines can accommodate different bag styles and sizes with ease. Additionally, they can handle a wide range of paper grades and thicknesses, providing flexibility in material selection.

3. Quality and Precision:

One of the key advantages of high-speed paper bag machines is their ability to deliver consistent quality and precision in every bag produced. Advanced control systems ensure precise cutting, folding, and gluing, resulting in uniformity in bag dimensions and seam strength. This level of quality control is essential for meeting stringent industry standards and satisfying customer expectations.

4. Cost-Effectiveness:

Investing in a high-speed paper bag machine offers long-term cost savings for manufacturers. By increasing production efficiency and minimizing material wastage, these machines help lower production costs per unit. Moreover, their durability and reliability ensure minimal downtime, maximizing operational uptime and overall equipment effectiveness (OEE).

5. Environmental Sustainability:

In alignment with the growing emphasis on environmental sustainability, high-speed paper bag machines contribute to reducing the ecological footprint of packaging production. By utilizing renewable and biodegradable materials, such as paper and water-based adhesives, these machines support eco-friendly packaging solutions. Additionally, their energy-efficient design helps conserve resources and reduce carbon emissions.

Conclusion:

In conclusion, the high-speed paper bag machine stands as the best choice for manufacturers seeking to meet the increasing demand for paper bags efficiently, cost-effectively, and sustainably. With its unparalleled speed, versatility, quality, and environmental credentials, this advanced machinery represents a strategic investment for businesses looking to thrive in the evolving landscape of packaging manufacturing.